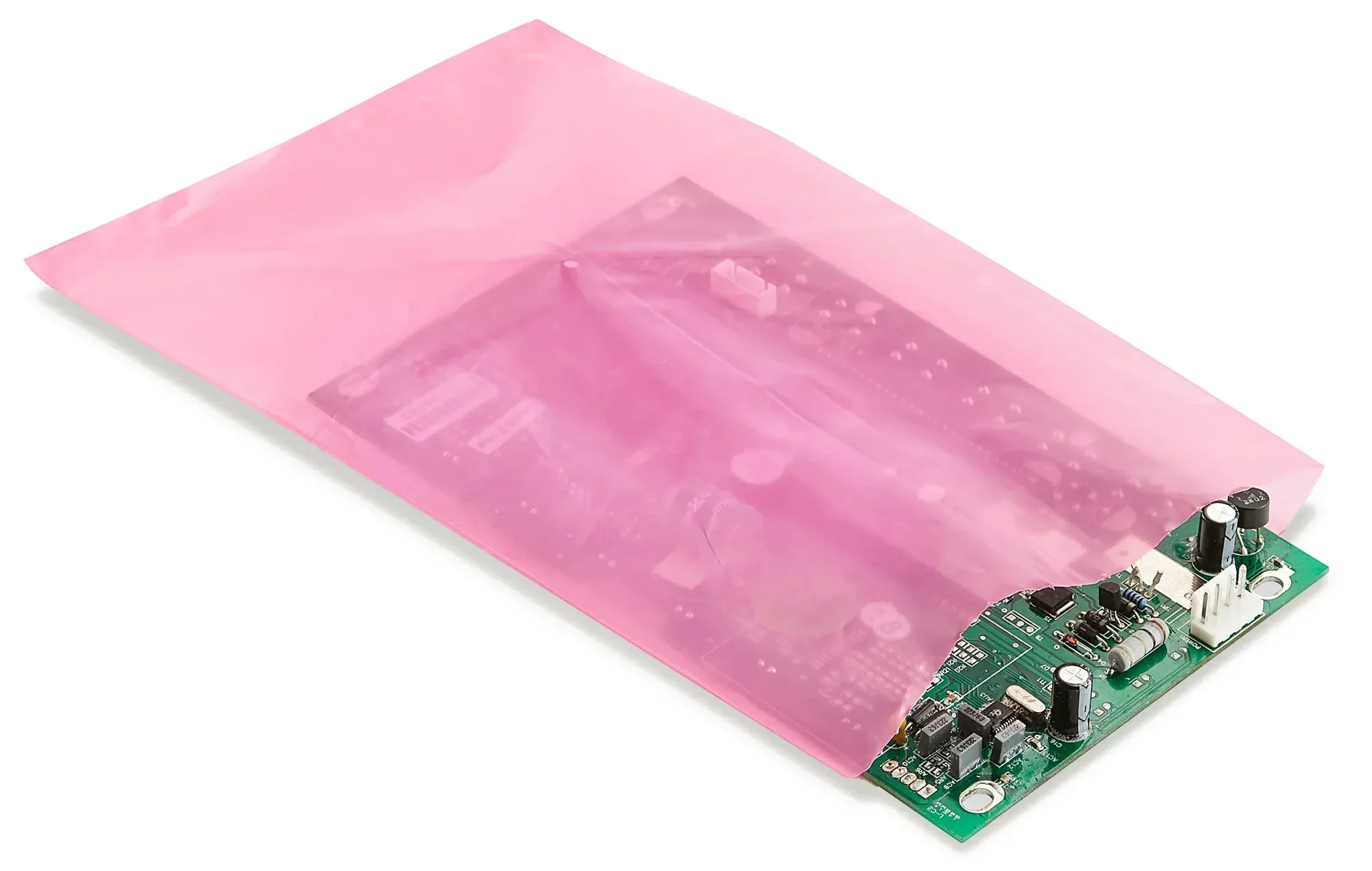

ESD Anti static Bag

Thương hiệu: Proline.vn

Status: In Stock

Product description

What is an ESD Shielding Bag?

An ESD shielding bag, also known as an anti-static bag or a static shielding bag, is a specialized packaging material designed to protect electronic components and devices from ESD. These bags are made of multiple layers of plastic with a metal layer in between, which acts as a barrier against electrostatic charges. The outer layer of the bag is usually made of static dissipative polyethylene, while the inner layer is made of aluminum or metallized polyester. This combination of materials creates a Faraday cage effect, which prevents any external electrostatic charges from reaching the contents inside the bag.

How does an ESD Shielding Bag Work?

ESD shielding bags work on the principle of electrostatic discharge. When two objects with different levels of electric charge come into contact, there is a transfer of electrons between them, resulting in a sudden flow of electricity known as electrostatic discharge. This discharge can range from a few volts to thousands of volts, and it can cause serious damage to electronic components and devices.

ESD shielding bags prevent this discharge by providing a low resistance path for the electric charge to flow through. The outer layer of the bag is slightly conductive, allowing any static charges to dissipate slowly, while the inner layer is highly conductive, providing a direct path for the charge to flow through. This way, the contents inside the bag remain protected from any external electrostatic charges.

Why are ESD Shielding Bags Important?

ESD can cause irreversible damage to electronic components and devices, leading to costly repairs or replacements. It can also affect the performance and reliability of these items, which can be a major concern in industries such as aerospace, defense, medical, and automotive, where precision and accuracy are crucial. ESD shielding bags provide a reliable solution to protect these sensitive items from ESD during handling, transportation, and storage.

Types of ESD Shielding Bags

There are various types of ESD shielding bags available in the market, each designed for specific purposes. Let's take a look at some of the most common types:

- Metalized Shielding Bags - These bags have a thin layer of aluminum or metal deposited on the surface, providing excellent protection against ESD.

- Static Dissipative Shielding Bags - These bags are made of a special type of plastic that has a low surface resistance, allowing any static charges to dissipate quickly.

- Moisture Barrier Bags - These bags have an additional layer of moisture barrier material, such as polyethylene or nylon, to protect the contents from moisture and humidity.

- Conductive Bags - These bags are made of a conductive material, such as carbon-filled polyethylene, which provides a direct path for the electric charge to flow through.

- Pink Anti-Static Bags - These bags are made of pink-colored polyethylene, which contains an additive that helps to dissipate any static charges.

Proper Handling and Storage of ESD Shielding Bags

To ensure the effectiveness of ESD shielding bags, proper handling and storage techniques must be followed. Here are some best practices to keep in mind:

- Keep the bags sealed - ESD shielding bags should always remain sealed until they are ready to be used. This prevents any external electrostatic charges from entering the bag.

- Use caution when opening the bag - When opening the bag, make sure to do it slowly and carefully to avoid generating any static charges.

- Avoid contact with conductive surfaces - ESD shielding bags should not come into contact with any conductive surfaces, as this can create a path for the electric charge to flow through.

- Store in a cool, dry place - ESD shielding bags should be stored in a cool, dry place away from direct sunlight, moisture, and humidity.

- Do not overfill the bag - Overfilling the bag can cause the contents to come into contact with the inner layer, compromising its effectiveness.

- Use proper grounding techniques - When handling ESD sensitive items, it is crucial to use proper grounding techniques to prevent any static charges from building up.

Testing and Certification for ESD Shielding Bags

As mentioned earlier, it is crucial to choose ESD shielding bags that have been tested and certified by reputable organizations. These certifications ensure that the bags meet industry standards for ESD protection. Here are some of the most common certifications to look for:

- ANSI/ESD S20.20 - This standard specifies the requirements for an ESD control program to protect electronic devices from ESD.

- MIL-PRF-81705E - This military specification outlines the requirements for packaging materials used to protect electronic components and devices from ESD.

- ASTM D882 - This test method measures the tensile properties of thin plastic sheeting used in ESD shielding bags.

- IEC 61340-5-1 - This international standard provides guidelines for establishing, implementing, and maintaining an ESD control program.

Sản phẩm đã được thêm vào giỏ hàng

Tiếng Việt

Tiếng Việt

Korean

Korean

Russian

Russian

Japan

Japan

English

English

0903.235.515

0903.235.515

-large.webp)